Depending upon speed, we have different types of construction in an overhead catenary of electric traction systems. The elasticity of the catenary over the span between supports varies.

Maximum elasticity occurs at the midpoint of the span and is proportional to the length of the span. But, minimum elasticity occurs near the supports and is independent of span. An increase in span length causes elasticity to become more uneven. If the span decreases then the number of supports and cost increases.

An increase in dropper spacing near mid-span does not affect elasticity but, near the supports elasticity is improved. With irregular dropper spacing (long spacing at supports and short spacing at mid-span), more even elasticity is obtained. Let us see how uniformity in elasticity is achieved with different types of catenary constructions in electric traction as the operating speed increases.

Single Catenary Construction :

The contact wire in the overhead equipment of the electric traction system is supported by another wire known as the Catenary or Messenger wire. The catenary provides support to the contact wire supplying power to the locomotive. The below figure shows the construction of a single catenary overhead line.

The main parts of the single catenary overhead line are,- Contact wire,

- Droppers,

- Catenary or messenger wire,

- Insulators and supports.

Contact Wire :

Contact wire is the wire which will be in contact with the pantograph. The pantograph collects the current for the locomotive from the contact wire. It is solid grooved wire made of 107 Sq.mm copper or cadmium copper wire.

Droppers :

The contact wire is suspended and leveled by droppers. Droppers are 65 Sq.mm cadmium copper cables. The first two droppers are at a distance of 2.25m and 6.75m respectively from the mast and the following droppers are heavily spaced at 9m. The droppers pass the power from the catenary wire to the contact wire.

Catenary or Messenger Wire :

The catenary or messenger wire is of steel wire with more strands that pass the power from the power supply to the dropper and hence to the locomotive. It is fixed with considerable sag between masts to keep the contact wire leveled at different temperatures, wind, and weather conditions.

For heavy currents in the dc overhead system, an auxiliary messenger wire is provided. The span (distance between support structure) of catenary wire may be from 45 to 90m with sag from 1 to 2m for straight track.

Insulators and Supports :

The catenary wire is supported by mast on insulators. The masts are spaced at a distance of 45m to 90m. The height of the contact wire to the rail varies from 3.6m to 5.80m depending on the type of tracks and services.

This type of catenary construction provides sufficient flexibility for speeds up to 120kmph without any difficulty for current collection. It is relatively less costly and easy to erect and maintain. It is suitable for most lightweight ac systems for branch and loop lines and secondary routes where operating speeds are low.

The current collection becomes difficult when operating speed increases. Due to uneven elasticity, at high speeds, the pantograph will lose contact with the contact wire. Therefore, at higher speeds where heavier conductors are used, the operation can be improved by using more complicated supporting arrangements between the contact and main catenary wire such as,

- Compound catenary construction,

- Stitched or Modified Y simple catenary construction,

- Modified Y compound catenary construction,

- Continuous mesh catenary construction.

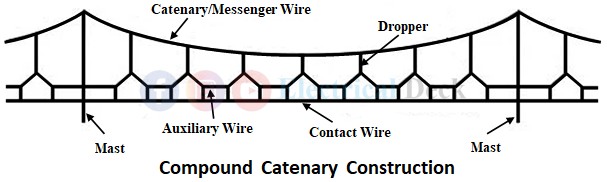

Compound Catenary Construction :

It consists of three wires, the main catenary, auxiliary or intermediary catenary, and contact wire in the same vertical plane as shown in the below figure. The contact wire is suspended from stranded cadmium copper auxiliary catenary by solid wire loop droppers which are free to slide vertically on the auxiliary wire and fixed to the contact wire.

An auxiliary wire is suspended from the main catenary wire by solid droppers. The purpose of the auxiliary catenary is to increase current carrying capacity and provide uniform elasticity. This construction enables automatic tensioning to be applied to the contact wire without causing displacement of the supporting bracket assembly.

Stitched or Modified Y Simple Catenary :

This type of construction has a short length of stitch catenary, the ends of which are attached to the main catenary at points 5m or 10m on each side of supporting points.

By provision of stitch wire in the catenary, variation in elasticity is reduced which improves current collection. With 20m "Y" the push-up is fairly constant but it is more prone to oscillations set up by the waves on both sides of the pantograph. A 10m "Y" is normally adopted for speeds of about 140kmph. The construction of the modified Y simple catenary is shown below.

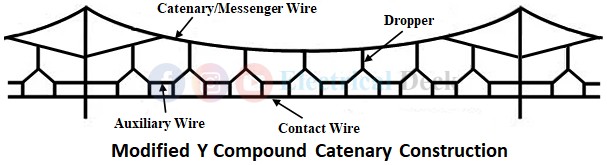

Modified Y Compound Catenary :

Modified Y compound catenary is a combination of the "Y" structure with a compound catenary system as shown in the below figure. This system has good push-up characteristics in addition to good current collection characteristics.

The drawbacks of this construction are the balancing of tension during stringing is difficult on account of short pieces of Y wire being used, the deformation of wire structure with the passage of time is feared and difficulties are involved in its installation and maintenance.

Effect of Speed On Catenary :

The type of construction of catenary to be used is primarily determined by the train speed. The effect of train speed on current collection by the pantograph can be determined if the behavior of overhead line under the passage of the pantograph is understood.

When contact speed exceeds 120kmph, a contact break may occur in the simple catenary system. To avoid contact breaks, the modifications in the construction of the catenary depending on train speed are given below.