When a conductor is stretched between two supports, sag is produced which is inversely proportional to tension in the conductor. For spark-less current collection under high speeds, the contact wire should remain horizontal during erection and under all conditions of temperature and pressure.

In unregulated overhead equipment, temperature compensation is not provided but sag and tension are adjusted such that the contact wire remains horizontal at the time of installation. With this arrangement, the contact wire tends to sag or hog depending upon whether the atmospheric temperature is more or less than the temperature at the time of erection.

This type of overhead equipment is not suitable for current collection on mainlines as tension varies inversely with temperature. At high speeds i.e., in mainline service, stiffness of the line must be maintained.

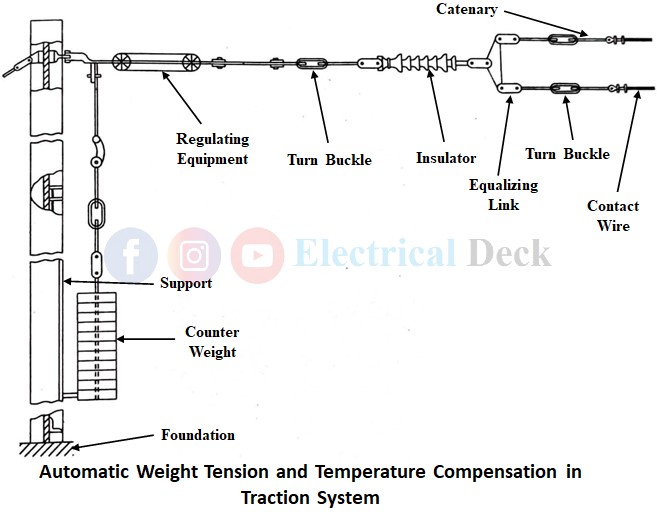

Since sag is dependent upon the tension in the wire, the contact wire should have the same level under all weather conditions, it is necessary to keep the tension in the catenary and contact wire constant under all temperatures. This can be obtained by using an automatic weight tension device on both ends of the line as shown in the below figure.

Construction and Working of Automatic Weight Tensioning Device :

The tensioning device consists of a pulley block or a winch with a suitable reduction ratio placed on both sides of the catenary and contact wire as shown below. When there is a variation in the temperature due to climate change, the pull force by the counterweights adjusts and maintains the tension in the contact wire and catenary. The weight of the pulley blocks will be around 400kg and the tension in the contact wire and catenary is around 1000 kg.

As the tension is increased, the overhead conductor becomes more uniform. The maximum tension length is determined by the extent to which variation in the length of the equipment due to variation in the temperature from ambient could be taken up by the automatic tensioning device. To avoid to and fro oscillations of the overhead line, it is fixed at the center called anti-creep.