The rating of the motor selected in industrial applications depends on the load conditions or duty to which it is subjected. Among different types of load conditions, continuous and intermittent are the two main types of industrial loads under which the motor is required to operate. Let us learn about continuous and intermittent duty and the differences between them.

Continuous Duty :

Continuous duty is the load on the motor for a long time i.e., the loads for which the motor operates under the same condition for a long duration of time is known as continuous duty. The below load cycle shows the representation of continuous duty.

In the above curve 'N' is the operation motor with constant load and θmax is the maximum temperature attained. It can be observed that for a continuous load operation, the temperature will go on increasing until it reaches a steady-state value. Thus it is necessary to calculate the exact amount of power needed by the drive due to the following reasons.

- If the motor rating is more than the required drive, then the motor will operate less than full load value, which in turn reduces the efficiency and power factor.

- If the motor rating is less than the required drive then the motor will get overheated and subsequently the motor will burn out.

Thus for continuous duty, a correct selection of motor should be selected based on thermal calculations and average power in order to avoid undesirable motor operation. Continuous duty is also known as constant duty. Some examples of continuous duty are fans, centrifugal pumps, blowers, paper mills drives, compressors, conveyors, etc.

Intermittent Periodic Duty :

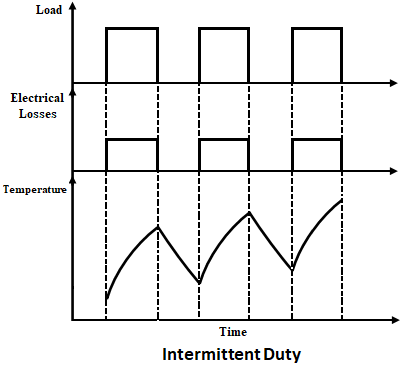

In intermittent duty, the load is connected to the motor for a specific period of time after which no load is connected to the motor for a specific period of time. In other words, when the motor is alternately subjected to constant load and standstill duration then the type of duty is called Intermittent duty. The intermittent duty cycle of the motor is of two types,

- The motor is loaded for short time and then it is shut down for a very long time. A sufficient amount of cooling of the motor to ambient temperature is achieved during the OFF load-interval itself as shown below.In the above load cycle, 'N' is the operation motor with constant load, 'R' is the interval where no load is applied (rest period), and θmax is the maximum temperature attained.

- In another type of intermittent duty, the motor is loaded for some duration of time, and then it is shut down for a very short time. Due to this, a sufficient amount of cooling of the motor to ambient temperature is not possible. This results in rising in the temperature of the motor with a rise in the time of operation. Thus, while selecting the motor, thermal calculation and average power will be considered.

Some examples of intermittent duty are lifts, cutting, escalators, cranes, presses, drilling machines, etc.

Difference Between Continuous and Intermittent Duty of Motor :

| Continuous Duty | Intermittent Duty |

|---|---|

| Continuous duty means the loads for which the motor operates continuously for a long time under the same conditions. | Intermittent duty means the loads for which the motor is loaded for short time and then it is shut down either for a long duration or a very short duration. |

| The duty cycle is simple and has high efficiency as it can stabilize the temperature as it runs. | The duty cycle is complicated as the motor frequently starts and stops. |

| For line-operated motors, these loads have constant torque. | For line-operated motors, these loads have the torque that changes suddenly. |

| These loads operate continuously. | These loads operate by taking intervals. |

| Examples: fans, centrifugal pumps, paper-making machines, etc. | Examples: Cranes, excavators, mixie, lifts hoisting machines, etc. |