The lightning arrester or surge arrester is the surge protection device used to limit the overvoltages in substations to a specified protection level. These devices are used to protect the conventional as well as gas-insulated sub-stations from temporary over-voltages, switching impulses, lightning impulses and to a certain extent, very fast transient over-voltages.

In the process of innovation for highly non-uniform V-I characteristics, metal-oxide based surge arresters have been identified as a complete solution for the protection of sub-station equipment against surge voltages. Let us see the construction and working of the metal-oxide lightning arrester.

Construction of Metal Oxide Lightning Arrester :

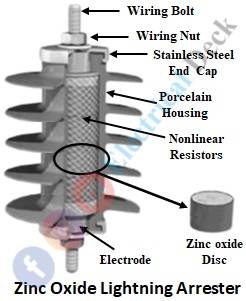

The design of a metal oxide surge arrester consists of discs that are made up of metal oxide and of all the metals, zinc oxide (ZnO) is the most commonly used metal due to which metal oxide surge arrester is also called as zinc oxide surge arrester.

Due to the nonlinear characteristics of the zinc oxide element, the series gap is not required in this arrester. Hence, this arrester is built without series-connected spark gaps due to which this type of arrester is also called a metal oxide gapless surge arrester or zinc oxide gapless surge arrester.

The above shows the constructional details of the zinc oxide (ZnO) surge arrester. The discs of metal oxide used in metal oxide surge arresters are arranged in a stack and are enclosed in a suitable insulator such as polymer or porcelain housing.

With the help of spring-loaded cups at the top and bottom, the stack is held in place. Electrodes are placed at both ends, one meant for the earth connection and the other for the line connection. The inner space remaining in the housing is completely filled with fiber-reinforced composite material.

Hence, the complete arrangement of the above-mentioned assembly forms a solid component consisting of threaded studs on either end. From the point of view of construction, a metal oxide or zinc oxide surge arrester is almost similar to that of a valve type surge arrester, but in this case, the valve element is a dense ceramic body made up of zinc oxide and some other metallic oxides.

Working of Metal Oxide Lightning Arrester :

Under normal operating conditions of the system i.e., when there is no surge and when the system is operating under rated voltage, the surge arrester will have a high resistance (almost infinite) to earth i.e., it acts as an open circuit.

On the occurrence of a switching surge, the metal oxide surge arrester responds very quickly to the surge voltages i.e., at the order of a nanosecond. The resistance of the surge arrester decrease at the very moment the surge switches in the system and hence leading to the discharge of very large currents to the earth.

Hence, the switching surge is safely diverted to the earth and the energy of the surge is absorbed by the arrester. Again, the system operates at normal rated voltage and the resistive property of the surge arrester improves due to which it again acts as an open circuit. Thus leaving the system voltage unaffected under normal conditions.

The blocks of metal oxide present in this surge arrester have high nonuniform voltage-current characteristics and hence these arresters are applicable for overvoltage suppressions. Metal oxide blocks carry continuous leakage current due to which a very important role is played by the thermal design of the arrester housing in effective dissipation of heat while the post current discharge takes place.

During the discharge of high currents in the metal-oxide surge arrester, the temperature of the block will increase. If the temperature goes on increasing, then it will lead to thermal runaway and if the temperature is less than the critical temperature, then the metal block will regain its original state for power frequency follow-up currents, whereas the residual voltage of the metal block is independent of temperature.

Hence, fine homogeneity of current flow during discharges is achieved, and also the absorption capability can be increased by connecting the metal block in parallel. Metal oxide or zinc oxide surge arresters are very much used for the protection of dry-type transformers and motor feeders in the switch gears with a rating of 6.6 kV.

The metal oxide lightning arrester has a negative temperature coefficient i.e., the resistance decreases as the temperature increases, which inter increases the leakage current through the surge arrester. The continuous flow of leakage current will develop heat in the arrester.

In the event of a fault, a full system short circuit current will pass and will generate high-pressure gases in it and internal pressure increases hugely as a result powerful explosion may take place. However, in order to avoid such failures and to reduce the pressure and heat inside the arrester, a pressure relief arrangement is provided. By this arrangement, the heat and the high-pressure gases are vented out.