The power transformer is the major and very important component of the power system. Also, the possibility of fault in a transformer is rare compared to a generator, but it must be disconnected as quickly as possible if the fault occurs. It requires highly reliable protective devices.

Generally, series fuses are employed for the protection of small distribution transformers. Whereas in the case of power transformers, automatic protective relaying equipment is needed for protection against possible faults.

Types of Transformer Faults :

The faults in transformers are mainly classified as,- Faults in the auxiliary equipment which is a part of the transformer,

- Transformer winding and connection faults, and

- Overload and External short circuits.

Faults in Auxiliary Equipments :

The faults in the auxiliary equipment of the transformer can cause the failure of the transformer windings. Therefore it is of great importance to detect these kinds of faults. The following are considered the faults in auxiliary equipment.

Core and Winding Insulation :

Minor faults, which develop in core and winding insulation may further develop into major faults if proper care is not taken at the initial stages. The failure in the insulation can be due to the poor quality of material used for laminations, core bolts, and joints or connections. These faults do not cause any interruption to the supply but must be cleared as soon as possible.

Gas Cushion :

Oil and insulation of the transformer get affected by the presence of oxygen and moisture in the gas space. The normal operating pressure within the tank varies widely hence, the pressure inside the tank must be monitored which can be done by a pressure vacuum gauge.

A second oil tank known as a conservator tank is mounted above the main oil tank to overcome the change in volume of the oil. It is partially filled with oil and takes the expansion and contractions of the oil in the main tank.

During this process, the air moves in and out of the conservator tank and is made to pass through a silica gel before entering the tank to prevent moisture and so only dry air enters.

Transformer Oil :

In order to protect the parts of the transformer from excessive heat, the whole assembly of the transformer is immersed in oil usually known as transformer oil i.e., transformer oil acts as a cooling medium. If the oil level drops below the specified level or if it losses its cooling property, then the parts of the transformer will get exposed to heat and may cause severe damage to the equipment and surroundings.

Hence, oil level indicators with alarm circuits are provided to ensure the oil level is maintained at a specified level and the oil is regularly checked for its cooling property.

Winding Faults and Connection Faults :

These faults occur due to unbalanced current or voltage and are serious in nature that causes immediate damage. Phase to phase faults such as faults between adjacent turns or coils short-circuits between turns on the HV and LV windings. Phase-to-earth faults on the HV and LV external terminals or on the windings.

The short circuits between the turns are mainly due to mechanical forces or insulation damage due to overload on a loose connection. A short circuit between the phases results in the flow of huge amount fault currents as well as the emission of a large amount of gas due to the decomposition of oil. These types of faults are easy to detect but they need fast clearance to avoid severe damage.

Overload and External Short Circuits :

The insulation of the windings is greatly affected by the loads. It will get deteriorated during overload conditions. Overloads and external short circuits raise the temperature of the windings and cooling system. To monitor winding and oil temperature, an alarm system is placed so as to permit the temperature limits at specified values. External short circuits are prevented by the transformer reactance.

Protection Schemes Employed for Transformer :

The scheme of transformer protection depends on the size of the transformer and its ratings. The different types of protection schemes available for transformers are,- Buchholz relay

- Differential protection

- Harmonic Restraint Relay

- Restricted earth fault relay

- Over-current protection

- Over fluxing protection

- Sudden pressure relay

- Thermal overload and temperature relays.

For transformers of rating 20 MVA, percentage differential protection is used as the main protection against phase faults. Overcurrent protection is used in addition as a backup for sustained external faults. The protection schemes that can be applied other than percentage differential protection are restricted earth fault protection, overcurrent protection, over fluxing protection, Buchholtz relay, and sudden pressure relays.

For transformers of rating 250 kVA, generally, overcurrent protection is employed as the main protection against phase faults. It can be provided simply by using fuses on the HV side.

Such transformers are installed in unattended substations and are not provided with circuit breakers and relays. The other methods that can be used for the protection of these types of transformers are restricted earth fault protection and Buchholtz relay.

Differential Protection of Transformer :

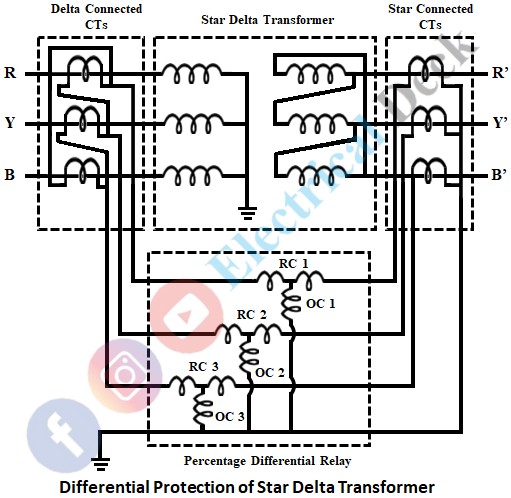

Differential protection of transformer is also known as Merz-price protection or circulating current protection used for protecting the transformer against phase to phase faults and phase to ground faults. The principle of operation of this protection scheme is based on the comparison of currents entering and leaving the transformer. The below shows the arrangement of percentage differential relaying as used for a star-delta transformer.

The CTs on the delta side of the transformer is connected in star and on the star side they are connected in delta. Because the line currents of star/delta power transformer have a phase shift of 30°. It is required that this phase displacement must be made zero by connecting the CTs in that fashion.

This means that for internal faults the line currents of the two CTs are such that the difference of currents is double the total current and is fed to the relay operating coil and the relay operates. For all external faults, the line currents of the two CTs should be equal in magnitude and in phase opposition so that the difference of the currents is zero, which makes the relay inoperative.

Buchholz Relay :

It is used for the protection of oil-filled transformers from incipient faults below the oil level. It is a gas-actuated relay used for the protection against almost all types of internal faults in a transformer.

They are usually employed for the protection of all oil-immersed transformers with ratings greater than 500kV. Buchholz relay can only be used for the transformers incorporated with a conservator tank as they are always connected between the main tank and the conservator tank.

Harmonic Restraint Relay :

This relay provides protection against the magnetizing inrush current i.e., the initial primary winding current of the transformer on no load, which is many times greater than the rated current. This protection is an additional arrangement to existing differential protection. It consists of a series LC circuit which allows only fundamental harmonic components to flow through the operating coils and all higher harmonics and DC components are diverted to the restraining coils.

Restricted Earth Fault Relay :

This type of protection is applied to safeguard a system against earth faults on the ungrounded star side or delta side of transformers. In restricted earth fault protection, the earth faults on the primary or secondary, or tertiary winding are restricted to the respective winding only, it does not affect the other side.

The connections for this type of protection are very simple. Three current transformers are connected in each phase of the transformer, and an earth fault relay is connected across the secondaries of the three CTs as shown below. Ideally, the output of the CTs is proportional to the sum of the zero-sequence currents in line and neutral earth connection.

When the primary winding is delta connected or has an unearthed star point, then an earth fault relay is connected in parallel to the secondaries of the primary side CTs to restrict the faults in the respective winding only.

For external faults, the vector sum of the line currents is equal to the current in the neutral. Thus relay will be inoperative. For internal faults, the vector sum of the CTs output currents is different from the current in the neutral. This causes the residual relay to operate if the fault current exceeds the pickup value.

Over-current Protection :

Two types of overcurrent relays are used for overcurrent protection,- Instant Time Current - Instantaneous overcurrent relays are used when the fault current exceeds its pick-up value. These overcurrent relays operate instantaneously without any time lag as soon as the current exceeds, the relays are set.

- Definite Time Current - In this type of relay, time grading is done such that the relay at the far end of the line operates first in case of fault and the relays in the earlier sections take a long setting time to operate. The main disadvantage of the graded relays is that the heaviest faults are cleared very slowly.

Over-fluxing Protection :

Over-fluxing means an increase in the magnetic flux due to an increase in supply voltage or decrease in the magnetizing current and iron loss and hence affecting the insulation of laminations. To avoid this, flux is to be controlled which is possible by controlling the V/f ratio.

Due to this reason, electronic circuits are employed along with relays, which continuously measure the V/f ratio, and when it exceeds 110% of the rated value, the circuit breakers are tripped within a minute. This time-lapse is provided deliberately in order to avoid tripping during transient operations or conditions.

Sudden Pressure Relay :

It is clear from its name that, this device responds to the rate of rise of pressure but not for rate pressure. It is used in transformers provided with gas cushions instead of conservators. This device provides protection from internal arcing which suddenly increases the pressure in the tank. So this relay trips the circuit breakers for internal arcing only.

Thermal Overload and Temperature Relays :

These relays sense the temperature of the transformer oil, which is heated up by the heat produced in the transformer winding. The technique employed for measurement is called the thermal image technique. Depending upon the temperature of the oil, the relay controls the cooling pumps and fans and also gives an alarm warning for overheating. The relay trips the circuit breakers at a maximum temperature of about 95°C. Also, they act as a source for the temperature indicators present on the control board.