Induction relay is a type of electromagnetic relay, that works on the principle of electromagnetic induction and it resembles a split-phase induction motor. The operating force developed will be due to the interactions of fluxes displaced in time and space in the rotor (movable element). The relays are mostly employed for the protection of lines and apparatus. Induction relays are classified into two types as follows,

- Induction disc relay,

- Induction cup relay.

Induction Disc Relay :

Principle of Induction Disc Relay :

The induction disc relay operates on the principle of electromagnetic induction similar to an induction motor. The torque produced in these relays is by the interaction of alternating flux with one of the magnets and eddy currents induced in the rotor (disc) with the other alternating flux.

The frequency of both the fluxes are same, but there will be a phase delay between them. These relays thus operate only on ac circuits. In this relay, the moving element is a disc on which the moving contact of the relay is fixed.

Construction of Induction Disc Relay :

The below shows the construction of the induction disc relay. It consists of a rotating disc mounted on a shaft placed between two electromagnets. The coils of the electromagnet are energized by the operating current in which the relay is connected for protection.

When there is a fault in the system, the coils get excited and produce a magnetic field. This magnetic field will induce eddy currents in the disc and these eddy currents will create their own magnetic field.

The magnetic field produced by the eddy currents when interacts with the magnetic field produced by the coil results in the production of torque on the disc. These cause disc to rotate and brings the moving contact towards the fixed contact which makes the trip circuit close.

Once the fault current falls below the pickup value, the spring resists the movement of the disc due to its restraining force and makes the trip circuit open by moving the moving contact away from the fixed contact. The time to close the contact depends on the contact travel distance which is set by a time delay.

Induction disc relays are of two types. They are,- Shaded pole type induction relay,

- Watt-hour meter type induction relay.

Shaded Pole Type Induction Relay :

The below shows the construction of the shaded pole type induction disc relay. In this, the main flux is split into two fluxes displaced in time and space with the help of a shading ring.

A shading ring or coil is made of copper (Cu) and encircles the part of the pole face of each pole at air-gap. Thus, two alternating fluxes are produced and are displaced in time and space. The air-gap flux of the shaded poles lags behind that of the non-shaded poles.

Hence, the torque is produced by the interaction of one flux with the eddy current produced by another flux. This resultant torque rotates the disc, which in turn operates the relay contact mounted on it. A permanent magnet is provided to produce eddy current braking in the disc.

Watt-hour Meter Type Induction Relay :

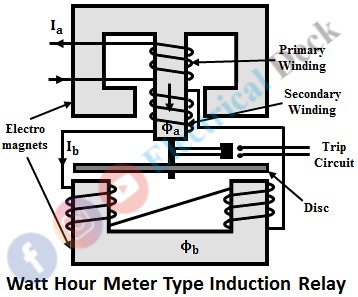

The construction of this type of relay is similar to the watt-hour meter which measures the electric power flowing through a circuit. It consists of two electromagnets and a disc that is free to rotate in between two electromagnets.

The upper electromagnet is E-shaped and the lower electromagnet is U-shaped. The upper electromagnet carries two windings (primary and secondary winding) on the central limb. While the lower magnet consists of secondary winding as shown below.

The two windings produce an alternating flux when they are energized. Let the fluxes be Φ1 and Φ2 respectively. The phase angle θ between the fluxes can be adjusted by using reactance in parallel with the secondary winding. The resultant torque produced by the interaction of flux of one of the magnets with the eddy currents of the other in the disc is proportional to Φ1 Φ2 sinθ.

Advantages of Induction Disc Relay :

- Induction disc relays are robust in construction.

- The operation of the induction disc relay can be easily controlled under abnormal conditions just by opening the secondary coil.

- By using induction disc relays, the current setting and the time settings can be obtained easily.

- Induction disc type relays are reliable and accurate.

- They can be used for overcurrent protection.

Applications of Induction Disc Relay :

- Induction disc type relays are used where reliability and robustness are needed.

- These types of relays find wide applications where slow-speed relays are required.

- Induction disc type relays are employed where adjustable operating time and time-delay feature is required.

- This type of relay is used where a high reset to pick-up ratio is needed.

Induction Cup Relay :

The construction of an induction cup relay is similar to an induction motor. The below shows the construction of the induction cup relay. The induction cup relay consists of the following parts,

- Stationary iron core (stator),

- Hollow cylindrical cup (rotor),

- Electromagnet, and

- Coils.

The stationary iron core acts as a stator which consists of two, four, or more poles. Nowadays it is constructed for 4 or more poles. The hollow cylindrical cup acts as a rotor similar to a disc in the other two relays. It is free to rotate in the air gap between electromagnets and stationary iron core.

Electromagnets create a magnetic field. It consists of two pairs of coils, when these coils are energized, flux is produced in the coils. These fluxes will have the same frequency but are displaced by an angle α from each other. These coils will then energize the iron core thus producing a rotating flux in the air gap.

Due to these fluxes, eddy currents are made to circulate in the rotor. Thus it will give rise to a force that acts on the rotor. So, the hollow cup rotates in the direction of the magnetic field between magnets and stationary iron core as the rotor of the induction motor.

This makes the fixed contacts of the trip circuit close and sends a trip signal to the breaker to open the circuit. There is a control spring backstop attached to the spindle of the cup to avoid rotation of the rotor continuously.