A Linear Variable Differential Transformer (LVDT) is an electrical transducer or sensor used for the measurement of physical quantities like displacement, force, pressure, acceleration, etc.

It works on the principle of mutual inductance, that generates an electrical signal proportional to the physical quantity applied which is to be measured. Let us see the various applications of LVDT.

Measurement of Displacement Using LVDT :

The measurement of linear displacement ranging from a fraction of mm to cm can be done by using LVDT. The displacement to be measured is applied to the movable core due to which a differential voltage will be produced at the output of the LVDT. The below shows the measurement of displacement using a linear variable differential transformer.

Working :

Let the emf induced in the two secondary windings are es1 and es2 respectively. In order to obtain a single differential output voltage, the two secondaries are connected in series opposition.

Under the normal condition, when there is no displacement is applied to the movable core. An equal amount of voltages will be induced in the two secondary windings. Since the secondaries are connected in series opposition the net output voltage will be zero.

Now when there is an upward movement in the core due to a displacement applied. The magnetic flux linkage with the secondary winding 1 will be more. This causes more voltage to induce in the secondary winding 1, and thus a differential output voltage with a positive value will be obtained.

Similarly, if the core moves downward, more voltage will be induced in the secondary winding 2. Now there will be a differential output voltage with a negative value. Hence the output voltage obtained is due to the displacement of the core. The measure of output voltage gives the displacement applied when calibrated.

LVDT Accelerometer (Measurement of Acceleration) :

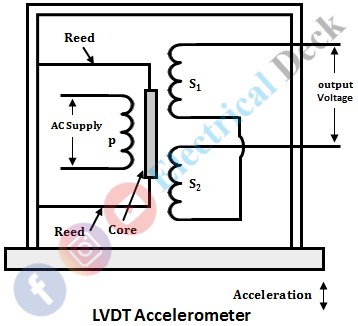

The LVDT accelerometer consists of one primary winding and two secondary windings having an equal number of turns. Between the primary and two secondary windings, a core is placed which acts as a sensing mass. This core is connected to the housing of the accelerometer by means of two flexible reeds.

When the acceleration to be measured is applied, vibrational displacement of core takes place due to which differential output voltage will be produced (at the output of LVDT). This output voltage gives the measure of acceleration.

Working of LVDT Accelerometer :

The accelerometer is attached to the object whose acceleration is to be measured. In the presence of acceleration, the vibrational displacement of the core occurs. Depending on acceleration the core moves up and down with respect to two secondaries.

Therefore, an differential output voltage will be generated at the output terminals. The magnitude of induced voltage (i.e., the differential output voltage of two secondaries) is proportional to the displacement of core and hence, gives the amplitude of vibration (i.e., acceleration).

Advantages of LVDT Accelerometer :

- They have good resolution.

- They offer very low resistance to the displacement of sensors compared to potentiometers.

- They can be used to measure high-frequency vibrations.

Measurement of Pressure Using LVDT :

Principle and Design :

An LVDT consists of one primary winding to which an ac supply voltage is given and two secondary windings. The two secondary windings are connected in series of opposite connections so that a differential output voltage can be obtained.

Between the primary and two secondary windings, a core is placed Depending on the position of the core, more or less output will be generated in the two secondary windings.

Now connect pressure sensing elements such as bellow or bourdon tube, to the core of LVDT such that the output displacement resulting from this transducer by the applied pressure will be transmitted to the core of LVDT as shown below.

Working :

When the core is placed between the primary and two secondaries in such a way that, it is symmetrically to two secondary windings, then the magnitude of the voltage induced in two secondaries are equal due to their series opposition connection. Therefore, the net output voltage is zero and this position is known as the null position.

When the pressure to be measured is applied to the bellow, the bellow deflects (expands upwards) and this movement is given to the rod of the core of LVDT. With this, the core will be lifted up and more voltage will be induced in the upper part of the secondary winding.

Therefore, a positive voltage is generated at the output (i.e., Eo = es1 - es2). In other words, when the core moved upwards from the null position a positive amount of voltage is generated at the output. This positive output will indicate applied pressure.

Now when the pressure is decreased the bellow contracts (comes downwards) and the core comes down from the null position causing more voltage to induce in secondary winding 2, which is denoted by es2, and the net output voltage is negative which indicates the decrease in pressure.

In this way, the LVDT type pressure transducer operates and produces a net output voltage that is proportional to the applied pressure.

Advantages of LVDT Pressure Transducer :

- Sensitivity is very high.

- Rugged construction.

- It has low hysteresis.

- It has very good repeatability.

Advantages of LVDT Pressure Transducer :

- It has poor accuracy.

- The performance of this transducer is affected by temperature change.

Measurement of Force Using LVDT or Proving Ring :

A proving ring consists of a high-grade steel ring with two loading bosses attached at the ends of one of its diameters with a displacement sensing device situated at the center of the ring as shown in the figure below.

When the force is applied on the loading boss, the ring tends to distort and this distortion is directly proportional to the applied force. This distortion is measured by a displacement sensing device. For low accuracy, the distortion is measured by a dial gauge or micrometer, whereas for high accuracy applications, LVDT is used as a displacement sensor. This displacement measurement is a measure of the force applied.

The proving rings may be used for both tensile and compression force measurements. The range of the proving ring is 2 kN to 2000 kN with an accuracy of 0.2 to 0.5 percent. Proving rings are high-precision devices that are extensively used for materials testing machines.