We know that the change in temperature of a conductor causes to change in its resistance. Hence the property of change in resistance due to change in temperature can be used for measurement of temperature, forming the transducer called Resistance Temperature Detector (RTD). It is a primary electrical transducer also known as Resistance Thermometer.

The resistance thermometer or RTD creates a change in resistance due to a change in temperature. The change in resistance is then converted into an electrical signal by a secondary transducer and the temperature is determined.

Construction of RTD or Resistance Thermometer :

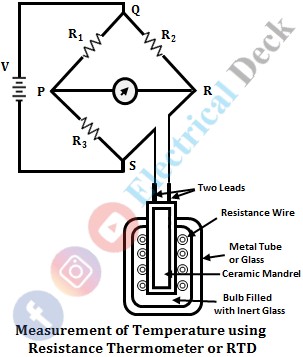

Resistance thermometers are made in the form of glass or metal tube which contains a resistance wire wound on a ceramic mandrel inside it and the leads of the resistance wire are kept outside the ceramic mandrel. The connection diagram of the resistance thermometer to the bridge circuit in the process of measurement of temperature is shown below.

The resistance wire of the RTD is mostly made up of platinum, nickel, or copper. The change in resistance of the wire is measured using a circuit known as a bridge circuit.

Material Used for RTD :

The material with which the RTD (i.e., resistance wire of RTD) is built should have high resistivity. Metals like platinum, nickel, nickel alloys are best suitable for making RTDs. The platinum is most widely used metal for RTD due to its high stability and temperature withstand.

The material used for RTD should possess the following requirements,- The variation of resistance with variation in temperature should be high.

- The sensing element of the RTD should not change its resistance permanently with temperature and its use over a period of time.

- There must be a linear response of change in resistance with temperature change over a wide range of temperatures.

- For measuring rapid changing temperature, the volume of material should be small. So that less heat is required to raise the temperature.

Since most of the metal conductors exhibit a positive temperature coefficient i.e., the resistance increases with an increase in temperature and vice versa, they are best suited for RTD applications. The below shows the resistance-temperature characteristics of different metals which is almost linear.

The copper, nickel, and platinum exhibit good sensitivity, high coefficient of resistance, and reproducibility. RTD's made up of nickel and nickel alloys are less expensive with good reliability compared to platinum.

Also, the temperature coefficient is a little higher than platinum, hence they are used in low range industrial applications. The platinum RTDs are used for high accuracy measurements and are best suited for many applications because of their stable operation and reproducibility.

| Metal | Resistance Temperature Coefficient | Temperature Range |

|---|---|---|

| Platinum | 0.39 | -260°C to 110°C |

| Copper | 0.39 | 0°C to 180°C |

| Nickel | 0.62 | -220°C to 300°C |

| Tungsten | 0.45 | -200°C to 1000°C |

Working of RTD or Resistance Thermometer :

The working principle of RTD is that the variation of temperature of a conductor causes to change in its resistance. When the resistance thermometer is placed where the temperature is to be measured and subjected to temperature variations. There will be a change in resistance of the conductor of the resistance thermometer. The amount of change that occurred in resistance can be given,

Where,- Ro = Resistance at zero temperature

- α1, α2, α3,...αn = Temperature coefficient of resistance

The above equation value of change is resistance is measured by bridge circuit (Wheatstone bridge) and temperature is determined.

Determination of Temperature Using Wheatstone Bridge :

Initially assume that the bridge is in the balance condition i.e., the four resistors connected in the four arms of the Wheatstone bridge are of equal value and the generated output is zero.

Place the resistance thermometer in the process or media whose temperature is to be determined and connect the two leads of the resistance thermometer in any one of the arms of the Wheatstone bridge (after removing the resistance of that arm). Here, the resistance thermometer acts as the fourth resistance element of the bridge.

When the temperature of the process changes, the resistance of the resistance wire also changes which in turn disturbs the balancing condition of the bridge.

Therefore, some output will be generated which is indicated by the galvanometer 'G' and it will give the value of temperature when calibrated. The more in the temperature change, the more disturbance in the balancing condition, and hence more will be the output indicated by the galvanometer