The bimetallic thermometer is a temperature sensor used for the measurement of temperature. It is a mechanical type (that uses nonelectrical method) temperature sensor that is constructed by two metallic strips. The two metallic strips used are such that their linear thermal expansion is different and the two strips are welded together forming a bimetallic strip.

The change in temperature of a media causes to change in dimension of the bimetallic strip that creates a mechanical displacement and deflects the pointer over a calibrated scale. This type of device is used for both domestic and industrial applications. The deflection of the pointer is proportional to the mechanical displacement and hence the temperature.

Construction of Bimetallic Thermometer :

The bimetallic thermometer is of solid expansion type of thermometer. The bimetallic strip or a bimetallic thermometer, or a bimetallic sensor is the temperature sensing element formed by joining two materials having different thermal expansion coefficients.

The two types of materials used are brass which has a high coefficient of thermal expansion and invar (a nickel-iron alloy) which has a low coefficient of thermal expansion.

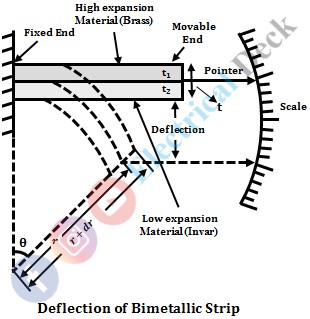

A bimetallic strip arranged in the form of a straight cantilever beam is shown above. The bimetallic strips can be available in cantilever, helical, flat types, and also in a spiral shape (however the working principle of all these types are the same).

Helical Shaped Bimetallic Strip Thermometer :

The helix or helical-shaped bimetallic strip thermometer is mostly used in industrial applications. The change in the temperature of the strip causes its contraction and expansion. The below shows the bimetallic strip thermometer with the helical shaped bimetallic strip with the bottom end fixed and the upper end left to free to move.

Spiral Shaped Bimetallic Strip Thermometer :

In this type of thermometer, the bimetallic strip is in a spiral shape. The tail end of the spiral strip is fixed and the end at its origin is left out free with a pointer attached to it as shown below. When the spiral strip is subjected to temperature change, deformation occurs and it will expand or contract. This type of construction uses less area but it is expensive.

Working of Bimetallic Thermometer :

One end of the cantilever-shaped bimetallic strip is fixed and the other end is left out free to move. When this element is subjected to a temperature that is to be measured, the strip senses the temperature. Due to this, the free or movable end of the cantilever will deflect.

This deflection of the cantilever beam is proportional to the temperature applied. If the free end of the strip is provided with a pointer scale arrangement, the pointer moves over the calibrated scale to indicate the applied temperature.

Expression for Radius of Curvature :

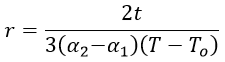

The radius of curvature of the bends of a cantilever (a straight bimetallic strip) can be given by,

Where,- t = total thickness of strip (t1 + t2)

- m = Ratio of thickness t1/t2

- n = Ratio of moduli of elasticity E1/E2

- (T - To) = Change in temperature

- T = Operating temperature

- To = Initial bonding temperature

- α2 = Higher coefficient of expansion

- α1 = Lower coefficient of expansion.

If the thickness and modulus of elasticity of both the materials are same then the above equation is reduced to,

Assume that the cantilever bimetallic strip is bent through a circular arc as shown in the figure above when subjected to temperature, then,

If the thickness of each metal forming the bimetallic strip is t/2 and if the expansion coefficient of invar α1 ≃ 0 and dr = t/2 then the above equation becomes,

The cantilever type bimetallic strip cannot be used for industrial applications since it exhibits small deflection and low sensitivity. By increasing the length of the bimetallic strip the sensitivity can be increased.

Therefore bimetallic strips with large lengths are available in the shapes of spiral and helical. In both cases, the thickness of the bimetallic strip should be maintained low compared to the radius of curvature. Bimetallic thermometers are generally employed in the range of-30 to 550°C.