Generally, Swinburne's test is the most popular testing method of dc machine to determine losses and efficiency. It is an indirect method of testing a dc machine performed without actually loading the machine. Since it is a no-load test, a series motor at no-load attains dangerously high speed. Hence, it is difficult to perform Swinburne's test on large series motors.

Therefore, Swinburne's test is only applicable for dc shunt and small series machines. This drawback can be overcome by performing field test. In this article let us see how the efficiency of dc series motors can be determined by conducting a field test.

Field Test of DC Series Motor :

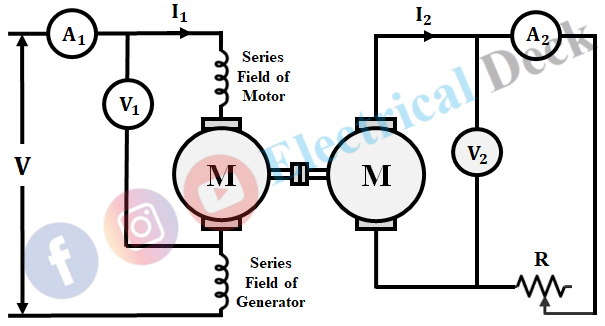

A field test uses two similar dc series motors, which are mainly used for electric traction works. In fields test, two similar dc series motors with their field windings connected in series are used to determine losses and efficiency.

The two machines are coupled mechanically in which one runs as a motor and the other as a generator driven by the motor. The electrical output from the generator is passed through variable load resistance R and dissipated as heat. The circuit diagram for fields test on dc series motor is shown below.

As they are rotating they have frictional losses and constant losses. The iron and frictional losses of the two are made equal by,

- Exciting the machines equally, which is achieved by joining the series field winding of the generator with the motor armature circuit.

- Synchronizing the machines by running them at equal speed.

Copper and iron losses depend upon Bm and frequency which in turn depends upon Bm flux and speed. Thus the iron losses can be maintained constant by satisfying the above two conditions. Load resistance R is varied till the armature connected in the motor armature circuit reads the full-load value. After this adjustment, different ammeter and voltmeter readings are noted.