Necessity of Transformer Cooling :

When the transformer is working or on-load or supplying or delivering current there will be some iron loss and copper loss takes place continuously. If the transformer works continuously these losses will come out of the transformer in the form of heat.

This heat should be driven out from the transformer core and windings otherwise the temperature of the transformer increases. This increase in temperature may damage the winding insulation and insulation or varnish between core laminations which in turn damage the entire transformer. The temperature of the surrounding equipment also may damage. Hence transformer cooling is very essential for proper operation.

Since there is no rotating part in the transformer which could produce draught, therefore it is difficult to provide a cooling arrangement to a transformer compared to motors and generators. For small rating transformers (5 to 10 kVA) the heat is dissipated through the tank surface but for machines of larger output additional means of carrying away the heat is to be provided.

The various cooling arrangements of a transformer are,- For Dry Type Transformer :

- Natural Air Cooling.

- Forced Air Cooling (Air Blast).

- For Oil Immersed Transformer :

- Oil Immersed Natural Cooling (ON type).

- Oil Immersed Forced Air Cooling (OB type).

- Oil Immersed Water Cooling (OW type).

- Oil Immersed Forced Oil Cooling (OWF type).

- Natural Air Cooling.

- Forced Air Cooling (Air Blast).

- Oil Immersed Natural Cooling (ON type).

- Oil Immersed Forced Air Cooling (OB type).

- Oil Immersed Water Cooling (OW type).

- Oil Immersed Forced Oil Cooling (OWF type).

Cooling Methods for Dry Type Transformer :

Natural Air Cooling :

Small rating transformers (up to 1.5 MVA and transformers in power supply, TVs, etc.) are naturally air-cooled. Here atmospheric air surrounds the tank to act as a cooling medium. The heat produced by the windings is transferred to the tank and dissipated to the surroundings through natural air and provides sufficient cooling to the transformer.

Forced Air Cooling :

For large rating transformers, the power loss is more and hence the heat production. Therefore, fans or air circulators are provided to force the air on the transformer surface to cool. An airblast transformer is an example of a forced-air cooling type method.

It is a dry-type transformer without water and oil (for cooling). The air blast cooling method is limited to voltages not exceeding 25 kV. The transformer is cooled by a forced-air circulation over the core and windings as shown below.

In the air-blast method, air with high pressure is forced continuously on the transformer core and windings, thus carrying out the heat. The air supplied is filtered to avoid dust from entering the ventilating ducts.

This type of transformer is used in cities and urban areas where oil is considered a fire hazard. The drawback of this arrangement is it doesn't provide better insulation due to the absence of oil thus increasing the insulation cost.

Cooling Methods for Oil Immersed Type Transformer :

Oil Immersed Natural Cooled Transformer (ON Type) :

In an oil-immersed transformer, the core with winding is placed in an iron tank filled with oil. The oil in the transformer tank observes the heat produced by the winding and transfers it to the transformer tank surface through conduction and convection methods. The heat from the tank surface is then dissipated to the surroundings. In large rating transformer tubes are provided on the tank surface to dissipate heat as shown below.

In this process, while transferring heat, the temperature of the oil increases and expands. A conservator tank is mounted on the transformer tank to observe this expansion of oil and a breather is provided to draw air-free moisture from the atmosphere.

Oil Immersed Forced Air Cooled Transformer (OB Type) :

The arrangement of this type of cooling system is similar to the naturally cooled transformer with core and winding immersed in the tank containing oil. Additional cooling is provided by forced air over the cooling surfaces.

A fan is mounted on the external surface of the tank and removes heat from the tubes by forced air as shown above. It is usually adopted in the transformer construction used at substations and generating stations.

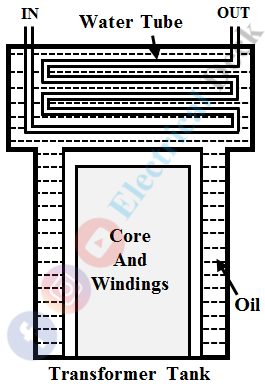

Oil Immersed Water Cooled Transformer (OW Type) :

The below shows the construction of an oil-immersed water-cooled transformer with a core and winding immersed in the oil and a water tube placed in the oil inside the tank. The water tubes are provided at the top of the tank where the temperature of the tank is very high.

The water is circulated through the tubes and observes the heat from the oil. The cooling tubes or radiators on the tank surface may or may not be provided.

Oil Immersed Forced Oil Cooled Transformer (OWF Type) :

In this type of transformer, the core and windings are immersed in oil and are cooled by forced oil circulation. The forced oil circulation is obtained by use of a centrifugal pump which is located at the oil inlet or outlet. The pump motor used for the purpose is designed to operate totally immersed in the cooling liquid being circulated.