In this method, the speed control of the dc motor is achieved by controlling the voltage applied across the armature terminals. It is introduced by the scientist sir Henry Ward Leonard in 1891 and named as a 'Ward Leonard Speed Control'. The variable voltage to the armature is supplied by using a motor-generator set. A desired wide range of sensitive speed control can be obtained by this method.

Principle of Ward Leonard Method :

In this method, the field winding of the motor M2 for which the speed is to be controlled is supplied by a separate permanently connected dc supply. The armature terminals of the motor are connected to a variable voltage supplied by a motor-generator set. The shafts of both motor and generator in the motor-generator set are mechanically coupled. The connection diagram for Ward Leonard's speed control is shown below.

Here the motor M1 drives the generator G running at an approximately constant speed. The motor M1 used can be either a.c. or d.c. type. The output voltage of the generator G is given to the armature terminals of the dc motor M2 (whose speed is to be controlled). The field of the generator is separately excited from the same dc supply supplied to the field circuit of a speed-controlled dc motor.

The connection of the generator field circuit is made through a reversing switch (not shown in the figure) and field regulator R. So that the connection makes it possible to easily reverse the generator excitation. Thus variable generator output voltage from zero to a maximum value in both directions can be obtained.

Thereby reversing the direction of the generator field current with reversing switch the polarity of generated voltage will also reverse and thus speed control of dc motor M2 in both directions will be achieved.

Nowadays, SCR circuits are used instead of motor-generator set to obtain variable dc voltage by rectifying the input ac power supplied through a transformer. Though it costs more when compared to the motor-generator set it reduces the maintenance. Also, this method provides the possibility to adopt automatic speed control through a feedback system.

Speed-Torque and Power-Speed Characteristics :

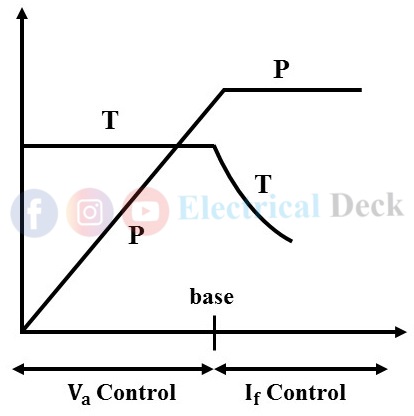

By adjusting the field current to its maximum value and excitation with rated voltage. Constant speed-torque characteristics with reduced speed below the base value can be obtained by reducing armature voltage.

For obtaining the speed above the base value, the field current is decreased by maintaining constant voltage across armature terminals. The decreased field decreases the torque on the motor as the speed increases.

Thus, a combined armature and field control is used over a wide range of speed control. Therefore nature of the power-speed characteristics is also revealed through the kind of control over torque-speed characteristics.