A transformer is a static device used to transfer electrical energy from one circuit to another circuit by mutual induction. The transformers are classified depending upon the service requirement for different purposes like at power generating plants, transmitting the generated power to the load centers, and distributing the transmitted power to the various consumers depending upon the voltage requirement.

Classification of Transformers :

The various types of transformers that are classified based upon,- Number of Phases :

- Single-phase transformer

- Poly-phase transformer

- 2-two phase transformer (Scott connection)

- 3-phase transformer

- Based on Construction :

- Core type

- Shell type

- Berry type

- Based on Function :

- Power transformers

- Step-up transformers (k > 1)

- Step-down transformers (k < 1)

- Distribution transformers always step-down (K < 1)

- Instrument transformers

- Potential transformer (PT)

- Current transformer (CT)

- Welding transformer

- Number of windings :

- Single-winding transformer (autotransformer)

- Multi-winding transformer

- Type of cooling :

- Air-cooled transformer

- Natural air cooled transformer

- Forced air-cooled transformer

- Induced air-cooled transformer

- Oil cooled transformer

- Oil-filled natural or self-cooled transformer

- Oil-filled forced air-cooled transformer

- Oil-filled forced water-cooled transformer

- Based on Location :

- Indoor transformer

- Outdoor transformer

- Frequency :

- Low-frequency (50 Hz or power frequency and audio frequency).

- High-frequency transformer, pulse transformer, radiofrequency, etc.

- Single-phase transformer

- Poly-phase transformer

- 2-two phase transformer (Scott connection)

- 3-phase transformer

- Core type

- Shell type

- Berry type

- Power transformers

- Step-up transformers (k > 1)

- Step-down transformers (k < 1)

- Distribution transformers always step-down (K < 1)

- Instrument transformers

- Potential transformer (PT)

- Current transformer (CT)

- Welding transformer

- Single-winding transformer (autotransformer)

- Multi-winding transformer

- Air-cooled transformer

- Natural air cooled transformer

- Forced air-cooled transformer

- Induced air-cooled transformer

- Oil cooled transformer

- Oil-filled natural or self-cooled transformer

- Oil-filled forced air-cooled transformer

- Oil-filled forced water-cooled transformer

- Indoor transformer

- Outdoor transformer

- Low-frequency (50 Hz or power frequency and audio frequency).

- High-frequency transformer, pulse transformer, radiofrequency, etc.

Explanation of Each Transformer :

Single-phase Transformer :

A single-phase transformer is used where the supply is of a single-phase alternating type. It mainly consists of two windings primary and secondary without any electrical connection, but are linked magnetically through a path of low reluctance called 'Core'.

The supply is given to the primary and according to the principle of faraday's law of mutual induction, emf gets induced in the secondary winding which is connected to load. The frequency of the secondary voltage will be the same as the primary voltage.

Poly-phase Transformer :

A three-phase transformer is formed by connecting three single-phase windings with each other. The connections are made in such a way that the primary windings of the three transformers are connected to each other and the other three secondary windings to each other. These can also be done by using three separate transformers.

The tree windings are placed at 120º with each other. A three-phase transformer is considerably less weight and occupies less floor area when compared to three separate single-phase transformers.

There are various methods available for transforming 3-phase voltages. But the most common connections are,- Delta-Delta (Δ - Δ)

- Star-Star (Y - Y)

- Star-Delta (Y - Δ)

- Delta-Star (Δ - Y)

It may often sometimes the necessary for a two-phase phase supply for a specific application where there is available three-phase power. A special type of transformer connection known as Scott connection or T-T connection is used to derive two-phase power from available three-phase power.

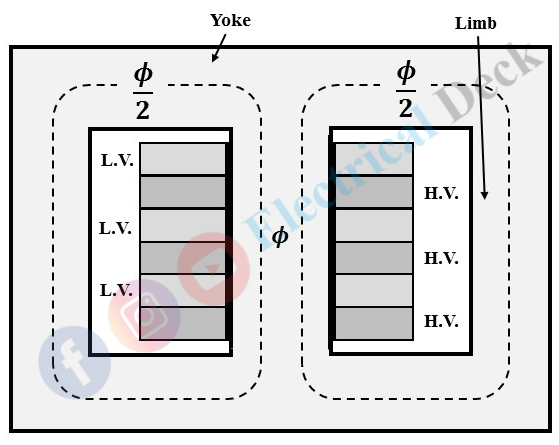

Core Type Transformer :

In a core-type transformer, the windings surround a considerable part of the core i.e., the windings are placed on two opposite limbs of the core. Core stepping gives a high space factor further reducing the length of the mean turn and I2 R loss. As the size or rating of the transformer increases the stepping of the core also increases. Generally, circular cylindrical coils are used for high voltage core type transformers, but this type of construction is used for small and medium capacity.

Shell Type Transformer :

In shell-type transformers, the coils are form-wound where both primary and secondary windings are surrounded by the core as shown below. This arrangement is also known as the 'Sandwich' type. Mostly shell-type construction is preferred for transformers of high voltage.

Power Transformer :

Power transformers are used for the transmission of power from the generating stations to the substation near load centers. These transformers are of the large size used to step up the voltage through a step-up power transformer at the generating station known as sending end.

The high voltage power is then transmitted and the voltage is stepped down through a step-down power transformer at the load centers known as the receiving end. They are designed to be operated at maximum efficiency at full load.

Distribution Transformer :

These transformers are comparatively smaller (hundreds of kVA) and operated at variable load conditions. The distribution transformer distributes power from the substation to the various loads depending upon the voltage requirement. They are connected directly to the load and are always step-down type.

Potential Transformer :

It is basically a measuring device used to measure high voltages. It is essentially a step-down transformer with a small voltage in the secondary winding. The high voltage from the transmission line is stepped-down and measured through small voltmeters. The conversion of the measured small voltage value into the actual high voltage value depends upon the voltage ratio of the potential transformer used.

Current Transformer :

Similar to the potential transformer, a current transformer is used to measure high currents in the transmission and distribution system. The potential transformer is connected in parallel to the line where voltage is to be measured whereas the current transformer is connected in series. Both potential and current transformers are known as 'Instrument Transformers'.

Auto Transformer :

An autotransformer is a special purpose transformer with one winding placed on an iron core. The part of single winding is common for both primary and secondary. This type of transformer is used where there is a need for continuous varying voltages. An autotransformer can be used as both a step-down and step-up autotransformer. Since it is a single winding construction, it requires less copper and is economically cheap.