Normally generation of power is usually at 3-phase from 11kV to 33kV. Transmission of generated power to the load centers is accomplished at higher voltages of 132kV to 400kV (or 700kV). For transmitting (sending end) the generated 3-phase power at such higher voltages it is essential to have a step-up 3-phase transformer.

Next, at load centers, the transmitted 3-phase power has to be stepped down to 33kV, 11kV, 440V, or 230V and distributed to the various consumers. For distributing the electrical power again it is essential to have a 3-phase step-down transformer.

Earlier years ago, the construction of a 3-phase transformer is by suitably interconnecting three single-phase transformers. But, nowadays instead of using three different single-phase transformers the whole primary and secondary windings of three transformers are built into a single core structure.

This construction is gaining more popularity because of its better improvement in design and manufacture and better acquaintance of operation. Let us see the construction of a 3-phase transformer.

Construction of Three-Phase Transformer :

Similar to the single-phase transformer the core of the three-phase transformer is constructed either in core type or shell type. The LV and HV windings of the 3-phases are placed on the three limbs of the core.

Core Type 3-Phase Transformer :

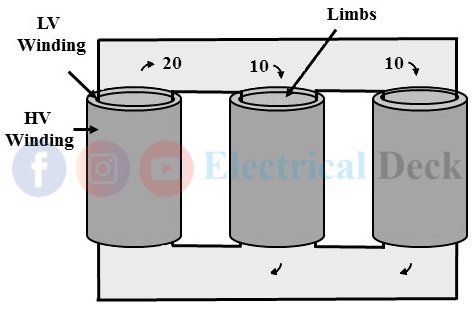

In a core type 3-phase transformer, the core is divided into three limbs in which each limb carries both high-voltage HV and low-voltage LV windings of the three phases. The flux produced by the primary ampere-turns will be linked by the secondary windings.

The primary and secondary of each phase on each limb is placed such that the LV winding is placed over the core limb and HV winding is placed on the LV winding. The main reason to place LV winding next or nearer to the core is the amount of insulation required is low to insulate the LV winding from the core as shown below.

The three core limbs of the three-phase winding are 120° apart. In a core type three-phase transformer at any instant, one limb out of three will act as a return path for the magnetic flux of the other two limbs.

The above represents the direction and magnitude of fluxes of a particular instant. It is seen that the sum of fluxes in the two limbs (downward direction) is equal to the flux in one limb (upward direction) that acts as a return path.

Shell Type 3-Phase Transformer :

A 3-phase shell type transformer can be combined with three single-phase shell-type transformers as shown in the below figure.

The shell-type core construction of a three-phase transformer is less commonly used. It consists of five limbs and the core surrounds the windings made on three limbs. The other two limbs (between phases) hold the three limbs as a one-unit and also provides a return path for the fluxes.

The whole construction is similar when three single-phase transformers are put side by side. Compared to the core type structure each phase has its independent magnetic circuit and return path for flux. Hence three phases are more independent in shell-type construction.

The entire core structure (either core or shell type) with windings is placed inside the transformer tank filled with oil. The winding connections of the three phases are made inside the transformer tank. The terminals of primaries and secondaries of three phases are taken out of the tank through bushings for external connections. The most commonly used three-phase transformer winding connections are,

Working Principle of Three-Phase Transformer :

The basic working principle of a three-phase transformer is the same as a single-phase transformer i.e., on mutual induction. The alternating supply is given to the primary windings and it induces an emf in the secondary winding. The amount of induced emf depends upon the number of secondary turns (either can be a step-up or a step-down transformer).

Advantages of Three-Phase Transformer :

Advantages of a three-phase transformer over three single-phase transformers are,- A three-phase transformer has considerably less weight.

- Three-phase transformer occupies less floor area.

- Three-phase transformer costs 15% less than three single-phase transformers of equal ratings.

- Only one unit (3-phase transformer) is to be handled.

- The busbars, switchgear, and protection equipment for a single unit transformer are less which makes the unit more economical.

Disadvantages of Three-Phase Transformer :

In a three-phase transformer, the three windings of three phases form one unit. This makes the whole transformer shut down in case of any fault in any one of the phases and it can be replaced or repaired. But, in the case of three single-phase transformers, the faulty phase transformer gets isolated and the system can run on open-delta with reduced efficiency.