Universal Motor is a single-phase commutator-type motor. It is a special type of motor because either it can be run on a.c. or d.c. supply. The main advantage of this type of motor is that it can be developed in ratings of some fractional kilowatt.

A series motor with a small fractional kilowatt rating (about 1/2 kW) that can run on both d.c. or 1-Φ a.c. supply is said to be a universal motor. This type of motor can usually operate up to the speed of 20000 rpm. Hence they are used where there is a need for small motors with low ratings like motors used in electric shavers, hair driers, etc.

Construction of Universal Motor :

Generally, there is no constructional difference between a universal motor and an ac series motor. We know that modifications are done to the dc series motor to work as an ac series motor. Similarly, small ratings (less than 1 kW) of such motors are known as universal motors. These motors are modified again so that they can operate on both ac and dc supply.

The field winding (series field) of a universal motor consists of fewer turns and increased armature turns. So that it provides a low reluctance magnetic path with laminated armature and field circuits. Due to reduced series field turns, the motors produce a field with low flux density. The construction of universal motors can be manufactured in two ways. They are,

Non compensated type (concentrated field), low power rating :

The construction of a non-compensated type of motor is the same as a normal dc series motor. Generally, it consists of 2 poles with a laminated magnetic path, the armature is wounded and connected in series with the field winding (main winding). The terminals of the armature are brought out through commutator segments and brushes as shown above.

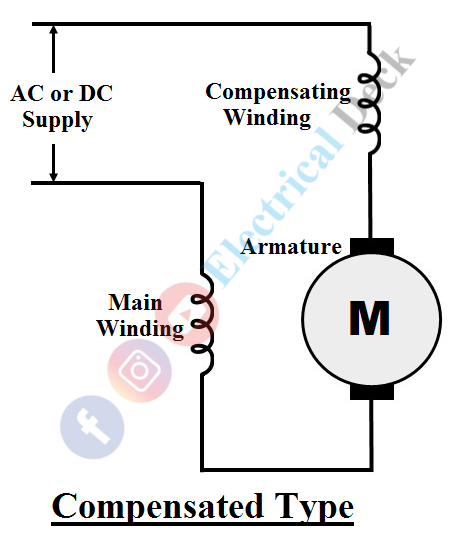

Compensated type (distributed field), high power rating :

The compensated type motor consists of two windings namely compensating and field (main) winding. The armature is of wound type as seen in non-compensated type motor. The three windings (main, compensated, and armature) are connected in series as shown in the above figure. The characteristics of this type of motor are better than the non-compensated type of motor, with high full-load operating speed, but the cost of this motor is more.

Working of Universal Motor :

The working principle of a universal motor is the same as dc series motor i.e., Lorentz Law. When either of the supply (AC or DC) is given to the motor. The main winding generates magnetic lines of force.

When the armature is placed in the lines of force produced by the field winding. Due to the series connection of armature conductors with the field conductors, the same current flows through the armature and field conductors. Therefore, torque is produced on the current-carrying armature according to Lorentz Law.

Here the direction of torque produced on the armature will be in the same direction even though the supply given is alternating. These motors can be available at speeds ranging from 3000 to 20000 rpm. As the speed ratings of this motor are very high, speed control methods are adopted to control the speed of the motor.

Characteristics of Universal Motor :

Universal motors are easily recognized because they use a commutator and brushes. Compensated type universal motor has better speed-torque characteristics compared to non-compensated type. Very high torque at low speeds can, therefore, be achieved. The no-load speeds of small universal motors may be much higher than their full-load speeds.

The full-load speed of a universal motor may be as high as 10.000 r.p.m When such high speeds are not required, gear trains are used to reduce the speed. The no-load speeds of small universal motors may be much higher than their full load speeds.

Speed Control of Universal Motor :

The following methods are used for speed control purposes of a universal motor,- Resistance Method

- Tapped Field Method and

- Governor Mechanism Method.

Resistance Method :

By varying the resistance R connected in series with the motor, the speed can be varied. It is used for sewing machines, and the variation of resistance is affected by means of a foot-pedal.

Tapped Field Method :

In this method, tappings are made on the field winding of the motor. Speed can be controlled by changing the tappings of the winding so that flux produced by the winding is changed, hence it changes the speed of the motor.

Governer Mechanism (Centrifugal Mechanism) :

We can see in home mixers or grinders that a switch is provided on the motor to control the speed at different levels this can be done by the mechanism of the governer.

A centrifugal switch is placed with the governer mechanism to keep the resistance in the circuit, and out of the circuit. It is used to control the speed of the motor by inserting the resistance in the circuit (which decreases the current flow value thereby decreasing the speed) and by removing the resistance from the circuit (i.e., when the switch is closed the current used to flow through the switch by decreasing the resistance and increasing the speed). A capacitor is used to reduce the sparking produced while switching.